The Briggs & Stratton fuel pump helps to keep the engine running by sending fuel to the engine. You won’t find this on all engines from Briggs & Stratton as most of them make use of gravity to send fuel to the engine rather than a fuel pump.

In this post, we are going to take a look at Briggs & Stratton fuel pump diagram and also talk about how to check if yours is working correctly and what to do if it is not.

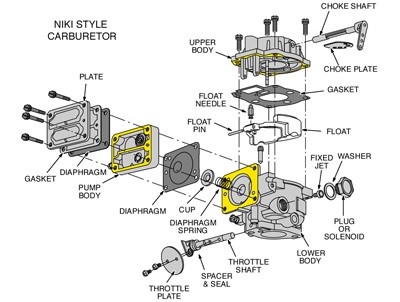

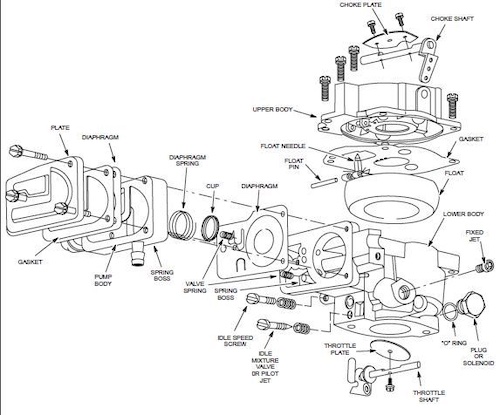

Briggs & Stratton Fuel Pump Diagram

What is the Briggs & Stratton Fuel Pump?

The fuel pump is needed to keep the engine running. It takes gas from the gas tank and through the carburetor and sends it to the engine. In Briggs & Stratton engines, a fuel pump is used when gravity cannot be relied upon to send gas through the fuel line (that is when the gas tank is mounted lower than the carburetor).

The Briggs & Stratton pulse-type fuel pump can come with either a plastic or metal body that develops pressure using the varying vacuum in the crankcase, created by the operation of the crankcase breather and the motion of the piston. The pressure needed to pump the fuel is drawn from a fitting on the crankcase cover or the dipstick tube.

Depending on your engine type, the fuel pump is typically mounted on the carburetor on the engine, near the fuel tank, or between the tank and carburetor.

How to Check Engine Fuel Pumps

If you notice any of the following problems with your engine, then you might want to check your fuel pump if it is sending gas to the engine as it is supposed to. A normally operating fuel pump shouldn’t have gasoline on the external of the pump or in the pulse line. Inspect the fuel pump to see if there is fuel in the location and if it needs to be replaced.

- At the base of the tank where you will find the fuel line, turn off the fuel valve (if you find one). If there is no fuel valve, use a fuel line clamp to stop the flow of gas.

- Loosen the mounting screws and remove the pump from the carburetor

- Check for cracks and other damages to the pump

- If you notice any cracks or damage, the fuel pump will have to be replaced.

How to Fix a Fuel Pump on a Briggs & Stratton engine

If you notice any problems or damages to the parts, you can simply replace the worn parts rather than going for the entire fuel pump replacement.

- Make sure the fuel valve is closed or the fuel line clamped, then remove the mounting screw.

- Disconnect the fuel hoses to loosen the clip and remove the screw.

- Soak the new fuel pump body in an all-purpose parts cleaner for up to 15 minutes and check for any damages, cracks in the hoses, or worn out parts.

- Discard old gaskets, springs, and diaphragms, and replace them with parts from the manufacturer’s repair kit.

- Place the new diaphragm, spring, and then cup over the pump chamber. You should also insert a valve spring.

- Install the diaphragm, gasket, and then the cover.

- Attach the fuel to the carburetor using the pump mounting screws

- Run the engine to verify that there are no leaks.

Sputtering Engine

If you notice that your engine starts to sputter especially when you run through tough or thicker grass on your lawn or whichever machine you’re using it for, then you might want to check your fuel line. The sputters could indicate that the engine is not getting enough fuel. You will have to inspect the fuel pump to check if it is working as it should. Take note that sputters might be an indication of other problems. It could be most likely due to spark plug trouble but you should also take note of the fuel pump

Surging Engine

If you notice your engine is surging, this could be due to a malfunction of the fuel pump. Engine surges can happen when the fuel pump sends too much fuel to the engine which means the machine will pick up and drop speed or performance. This won’t help the engine in the long run and won’t help you deliver a perfect job. There are also other reasons why engine surges could occur but you’re most likely dealing with a faulty fuel pump. Have it checked out before moving to other parts of the machine.

Dead Engine

If your engine is unable to start even after running checks, then you should take a look at the fuel pump. Chances are, it is not sending fuel to the engine to run it. In a situation that the fuel pump won’t transfer fuel, it could be that the fuel pump is clogged or died.

Instead of going straight to take apart the fuel pump, you should check the fuel lines to see if they are clogged. If not, you can go ahead to inspect the fuel pump and unclog it. You might want to know how it got clogged in the first place. You should always make use of your fuel filter and check your gas before pouring it into your fuel tank.

Power Loss

The engine needs fuel to run and without it, you won’t get the power to handle jobs. In some cases, your engine will be able to start and run normally even though the fuel pump is malfunctioning, however, if you start using your lawn mower or utility machine to handle tougher jobs, you might notice that the machine shuts off.

This could be due to the inefficiency of the fuel pump so the engine is not getting enough fuel to handle these jobs. The reason for this could be that the fuel pump is clogged or damaged. Depending on the severity, the fuel pump might have to be fixed or replaced. Take note that power loss could be due to a bunch of other problems and fuel pump issues is the least likely problem. However, you should not rule out the possibility of a fuel pump issue especially after you checked other parts of the machine.