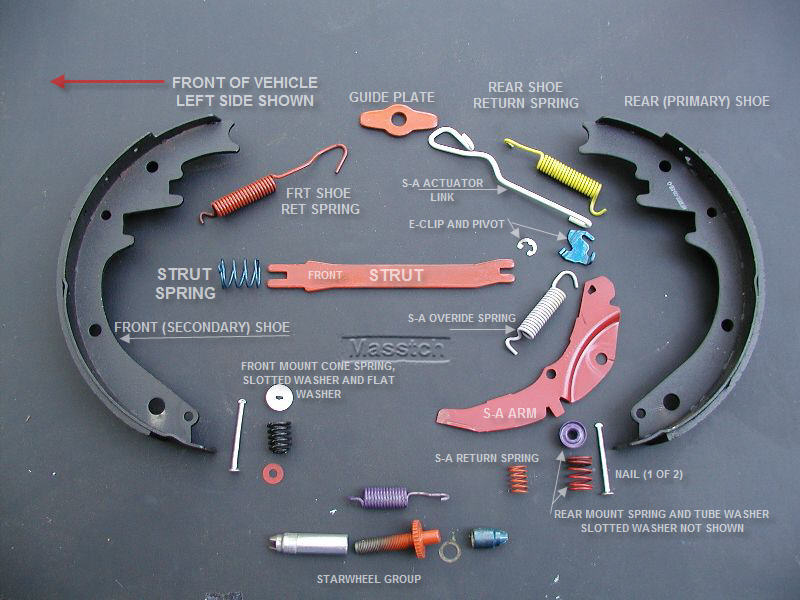

If you notice an abnormal sound in your braking system or a loose parking brake, you should check your Chevy rear drum brakes immediately. To do so, you will need the right tools as well as this Chevy rear drum brake diagram.

Chevy Rear Drum Brake Diagram

Symptoms of a Bad or Failing Brake Drum

A failing brake drum will affect the car’s ability to come to a stop when needed. If you notice any of these symptoms, you should get your car to the auto repair shop immediately.

Unusual brake pedal feel

When the drum brake starts to fail, you will notice inconsistent brake pedal and vibrations when braking. This means that the brake drums are worn excessively which could also cause shuddering or pulsating.

Scraping noises when braking

If you hear scraping or scratching sounds when you press the brakes then your drum brakes are failing. This happens when the brakes are excessively worn and only the metal plate remains which creates a metallic scraping noise when the brake is pressed. You will have to perform a thorough inspection of the brake drums and replace the whole brake drum and the brake shoes.

Loose parking brake

The hand brake or parking brake could become loose when the drum brakes begin to fail. As the drum brake wears, the brake shoes will not be able to squeeze against the inside of the drum easily. As a result, the parking will not work efficiently. You will notice that the car will slip a few inches when the parking brake is engaged. This problem could be also caused by a misadjusted brake cable or worn shoes. If you notice any of these symptoms, getting the car inspected if the necessary step.

How to Check Your Drum Brakes

Inspecting your drum brakes is a tedious task that requires taking out many parts of your vehicle to get to them. Using the steps below, you should be able to check and inspect your drum brakes

- Jack up your vehicle and remove the wheel. You might find a hubbed drum break with wheel bearings or floating drums that slide over the lug nut studs. If your vehicle has the hubbed drum type, take the grease cap off the hub’s end using a pair of combination slip-joint pliers. If you have a floating drum, simply slide the drum off the hub. Using a hammer, strike the floating drums to loose from the hub.

- The castellated nut has a cotter pin that sticks out of the side. Take note of how the legs are bent, how hot tight it is, and how it fits the nut. You can take a picture of it for future reference.

- Using needle-nose pliers, straighten the cotter pin and pull it out. Then slide the castellated nut or nut-lock-and-nut off the spindle. Wipe the nut if it is greasy.

- The outer bearing with the washer should be right in front of you. Slide the outer bearing and washer off the spindle. Then check the bearing for wear.

- Slide the drum as well as the inner bearings of the spindle.

- Inspect the inner walls of the drum for wear. These will appear as grooves. Burned places or deep grooves mean that the brake drums need to be replaced.

- Inspect the rear of the brake including the wheel cylinder to see if it is leaking brake fluid. Also, check the brake shoes for signs of wear, thin places, and bald spots.

Drum brake advantages

While the technology behind drum brakes is old, there are quite a few advantages that drum brakes have over their innovative disc brake counterparts

- Drum brakes will provide more braking force than an equal diameter disc brake.

- Drum brakes are designed to last longer due to increased friction contact area than a disc brake

- Drum brakes are cheaper to manufacture which means maintenance and replacements won’t require you to break the bank

- Rear drum brakes generate lower heat than disk brakes

- Drum brakes feature a built-in self-energizing effect that requires less input force than disc brakes

- The wheel cylinder of drum brakes are simpler to recondition than disc brake calipers

- Drums brakes have better corrosion resistance which gives them a slightly lower frequency of maintenance.

Drum brake disadvantages

While drum brakes come with many advantages, there are also some areas that they fail to keep up.

- Drum brakes are prone to excessive heating due to heavy braking which can cause the drum to distort and vibrate under braking.

- Under hard braking, the drum will increase by diameter due to thermal expansion, this means that the driver will have to press the brake pedal.

- Brake shoes could overheat to the point where they will be glazed. In addition, excessive drum break heating can cause the brake fluid to vaporize

- Maintaining a drum brake is quite tedious and time-consuming compared to disc brakes